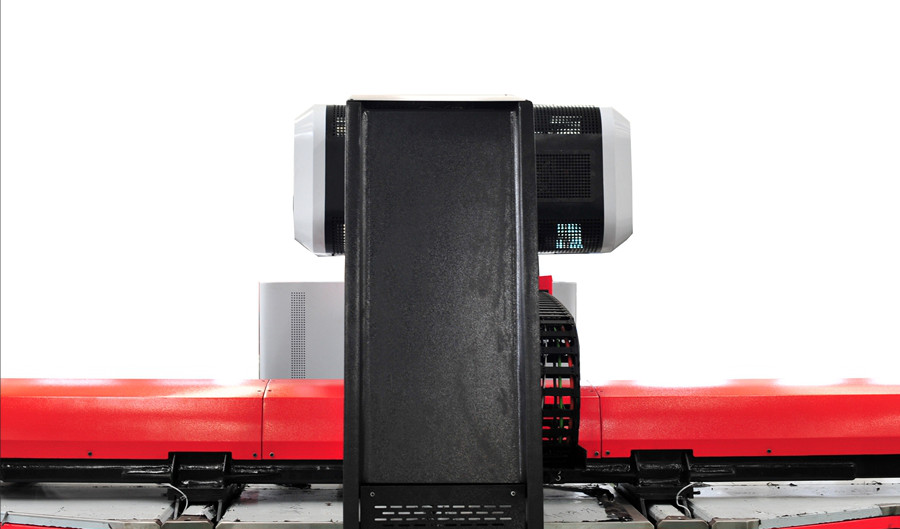

Imashini yo hejuru ya CNC Turret Imashini

1.

(1) Guhindura umuvuduko no guhagarara

a. Inkoni ya punch irashobora gutoranywa ukurikije ubunini bwurupapuro rwikora, kuzamura imikorere.

b. Umuvuduko wa punch urashobora guhinduka muri buri ngingo ya buri sitasiyo imwe,

c. imashini irashobora gutahura umuvuduko mwinshi mugihe cyo kwiruka ubusa n'umuvuduko muke mugihe cyo gukubita, murubu buryo, ubwiza bwa punch burashobora kunozwa neza, kandi mubyukuri nta rusaku mugihe cyo gukubita.

(2). Sisitemu iranga hamwe nuburinzi burenzeho hamwe nibikoresho byo gukingira birenze urugero.

(3). Imbaraga zo gukubita zirashobora guhita zihindurwa ukurikije uburebure bwurupapuro hamwe nintama yo kwiruka yintama kugirango ubwiza bwo gukubita bugere kurwego rwo hejuru.

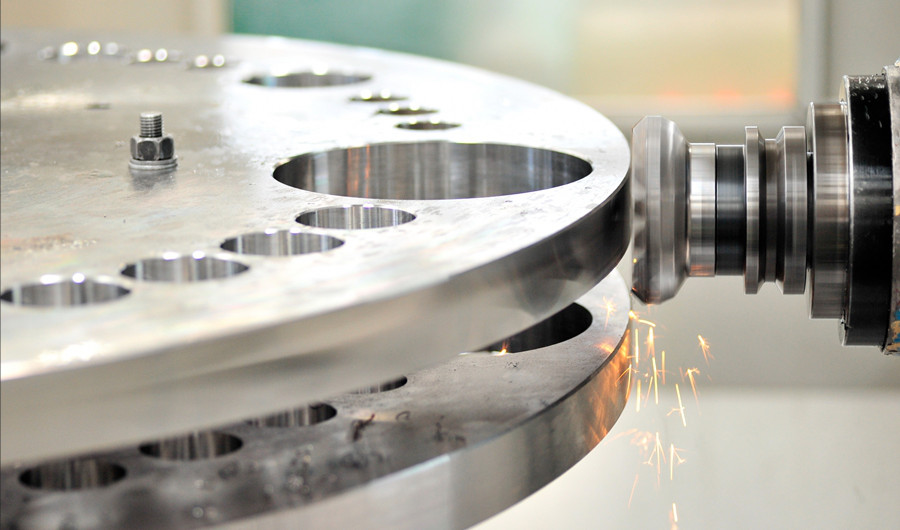

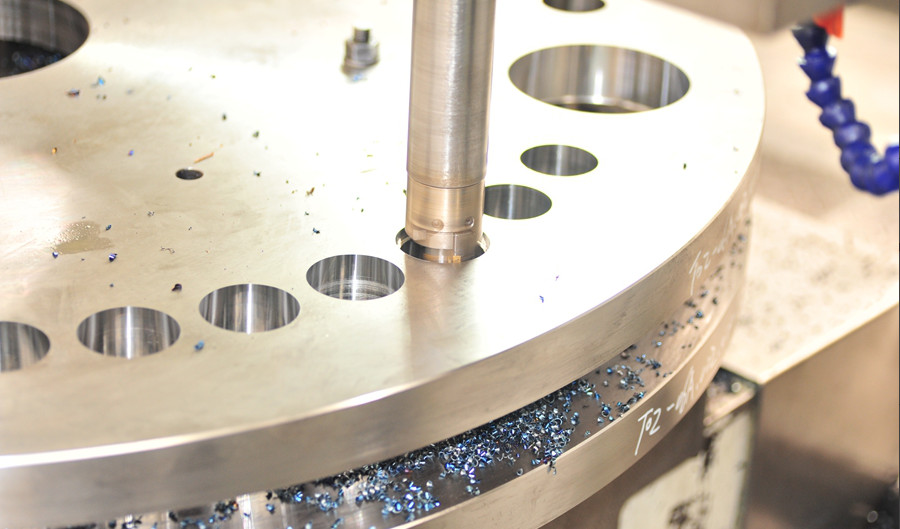

2. Turret hamwe na bushing ni inzira ebyiri

Taret itunganywa nigikoresho kidasanzwe kugirango tumenye coaxiality ya tarret yo hejuru no hepfo no kwagura ubuzima bwa serivisi bwibikoresho; igihuru kibisi cyoroshya imiterere ya tarret kugirango yongere ubuzima bwa serivisi; ibikoresho birebire birashobora gukoreshwa kugirango wongere umurongo ngenderwaho kandi wagure ubuzima bwa serivisi (kumpapuro zibyibushye).

3. Ibicuruzwa bitumizwa mu mahanga, amavuta yo kwisiga hamwe n’amashanyarazi byemeza ko imashini yose yizewe.

4.

5. Gukaraba cyane hamwe nu mupira bivanze bikora bigabanya urusaku no kunyeganyega mugihe cyo kwiruka kandi bikarinda urupapuro.

6. O-Ubwoko bwo gusudira ikadiri yahinduwe inshuro ebyiri, imihangayiko yasibwe burundu. Ikadiri yatunganijwe nubudage SHW impande zombi zitunganya pentahedron icyarimwe, ntagikeneye gukora umwanya wa kabiri.

7. Clamp ireremba hamwe nimbaraga nini zifata neza kugaburira neza; ubwikorezi bwuzuye butuma gukomera no kugenda neza kwa clamp.

8.

9. Auto-index yerekana inziga nini yinzoka ninzoka yinzoka, ikemeza neza neza. Inyandiko. ibikoresho bya diameter birashobora kugera kuri 88.9mm kandi auto-index irashobora kwagurwa kugeza kuri 4.

10. Imiterere ihuriweho nuburyo bwo gukora igare nigiti mugice kimwe, byongera ubukana kandi bizana imyanya nyayo. Imashini irashobora gukora cyane mugihe cyo kugaburira byihuse kandi igashyira iherezo ku gutandukana kwa X na Y.

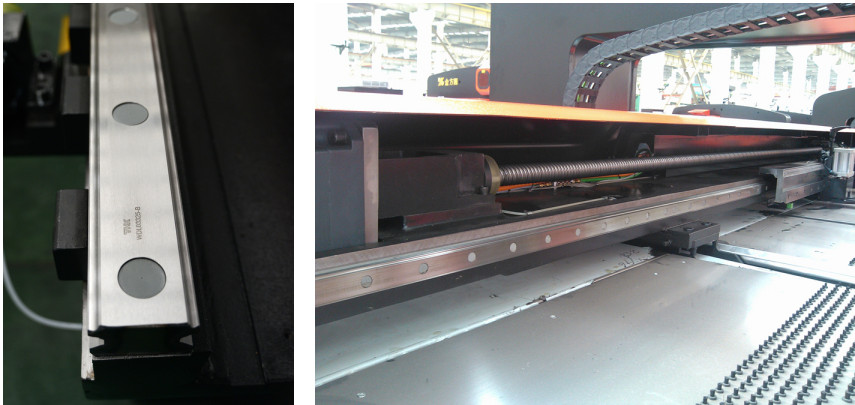

11. X axis: ifata moteri ya servo kugirango itware imipira ihanitse yimipira yabakozi kandi ubwikorezi bugaragazwa nuburemere bukomeye kandi bworoshye. Y. Iyi miterere irangwa nibiranga ubukana bwiza, urumuri muburemere, uburemere buke, hamwe nigisubizo cyiza muri sisitemu yose yo kugaburira, kwiruka neza kandi neza.

12. Sisitemu yo kwisiga yo hagati yashyizweho kugirango yohereze amavuta yo kwisiga aho ugereranije, kugabanya ubukana bwa buri jambo rikora no kongera ubuzima bwa serivisi.

13. Kurwanya anti-sheet-deformasiyo hamwe nimpapuro zo kurwanya anti-striping byemewe.

| Oya. | Izina | Qty. | Ongera wibuke |

| 1 | Urutonde | 1 set | |

| 2 | Icyemezo cyiza | 1 set | |

| 3 | Imfashanyigisho ya mashini | 1 set | |

| 4 | Igitabo gikubiyemo amashanyarazi | 1 set | |

| 5 | Igishushanyo mbonera | 1 set | |

| 6 | Igishushanyo cy'amashanyarazi | 1 set | |

| 7 | Porogaramu-Porogaramu Porogaramu Sisitemu Sisitemu | 1 set | |

| 8 | Igishushanyo cya DBN Igishushanyo | 1 set | |

| 9 | Igitabo gikubiyemo ibikoresho | 1 set | |

| 10 | Igitabo cya sisitemu ya CNC | 1 set | |

| 11 | Igishushanyo | 1 set |

| Oya. | Izina | Gauge | Qty. |

| 1 | Umutwe-Umutwe | 5.5 × 7-22 × 24 | 1 set |

| 2 | Kwimura | 200 | 1 oya. |

| 3 | Sock Head Spanner | S1.5-S10 | 1 set |

| 4 | Amashanyarazi | 100 × 6 | 1 oya. |

| 5 | Grease imbunda | HS87-4Q | 1 oya. |

| 6 | Amavuta yo gusiga pompe Compressor imbunda | SJD-50Z | 1 oya. |

| 7 | Imbunda ndende | 1 set | |

| 8 | Imiterere ya knob | M14 × 1.5 | 1 oya. |

| 9 | Kwegera | M12 PNP SN = 2 fungura | 1 set |

| 10 | Kwegera | M12 PNP SN = 2 hafi | 1 oya. |

| 11 | Spanner | T09-02.500.000-38 | 1 oya. |

| 12 | Umuyoboro wa gaze ya silinderi | 1 set | |

| 13 | Umuyoboro woroshye | Ø 12 | 1 oya. |

| 14 | Umuyoboro woroshye | KQ2H12-03AS | 1 set |

| 15 | Ibice by'ifatizo | 1 oya. |

| Oya. | Izina | Gauge | Qty. | Ongera wibuke |

| 1 | Ikibaho cyibikoresho | 3 nomero. | T02-20A.000.000-10C T02-20A.000.000-24A | |

| Ikibaho gikingira | 6 nomero. | T02-20A.000.000-09C Cyangwa T02-20A.000.000-23A | ||

| 2 | Isoko Ntoya ya clamp | M4x10 | 20 nomero. | T02-06,001,000-02 |

| M5x12 | ||||

| 3 | screw muri clamp Imbere yimbere | M8 x 1 x 20 | 20 oya. | |

| 4 | Gukata icyuma | 30T | 2 nom. | T09-16.310.000-0.1.2 |

| 5 | Imbere | M8 x 1 x 20 | 4 nomero. |

Sisitemu ya FANUC CNC ni sisitemu yihariye ya CNC yatunganijwe n’Ubuyapani FANUC cyane cyane hagamijwe guhuza ibiranga ubu bwoko bwimashini, kuzamura ubwizerwe bwimashini murwego runini.

I 、 Ibiranga Sisitemu

1. Igikorwa cyo gushushanya no gukubita;

2. Porogaramu yoroheje ya kode ya G kugirango ikorwe byoroshye;

3. Icyambu rusange RS232 icyambu gisanzwe kugirango ivugane na mudasobwa byoroshye;

4. Sisitemu yuzuye ya sisitemu ya servo yuzuye na sisitemu ya servo;

5.10.4 ″ LCD yerekana amabara;

6. Pulse encoder igice cya loop ibitekerezo;

7. Ububiko bwa EMS: 256K;

8. Gahunda yumurima, gahunda y'ibiro;

9. Kugaragaza Igishinwa n'Icyongereza;

10. Imikorere yo kwigana ibishushanyo;

11.Karita imwe nini ya PCMCIA ikarita yo kugarura ibipimo bya sisitemu, gushushanya urwego no gutunganya gahunda, no kumenya inzira kumurongo wa gahunda nini yo gutunganya ubushobozi;

12. Kwiyongera mubice bito, kugenzura imyanya ad servo kugenzura kugirango umenye umuvuduko mwinshi nigikorwa cyukuri;

13. Akabuto k'ibikorwa kuri panel karashobora gusobanurwa ukurikije ibisabwa nyabyo;

14. Umuvuduko mwinshi wihuta wibikoresho bya data hamwe numuyoboro muto;

15. Kwishyira hamwe, software yihariye. Igihe gito cyo gutangira, amakuru ntazabura niba ingufu zibuze gutanga gitunguranye;

16. Kubika ibice 400 bya porogaramu.

1. Ishoka y'umurongo: X, Y ishoka, ishoka izunguruka: T, C amashoka, punch axis: Z axis;

2. Imenyesha ryamakosa yumuriro nko gukubita.

3. Imikorere yo kwisuzumisha.

4. Imikorere yumupaka woroshye.

5. Kode ya Universal G ya porogaramu;

6. Imikorere yindishyi zikoreshwa;

7. Imikorere yindishyi zintera;

8. Imikorere yindishyi zinyuranye;

9. Imikorere ya coordinateur gutandukana;

10. Imikorere yo gusimburwa;

11. Imikorere ya AUTO, UBUYOBOZI mode Uburyo bwa JOG;

12. Imikorere yo gukingira clamp;

13. Imikorere yo gufunga igitabo cyimbere;

14. Imikorere ya progaramu ya parameter;

15. Imikorere ya porogaramu;

16. Imikorere yumwanya wihuse no gufunga punch;

18. Imikorere ya kode ya M;

19. Gahunda yuzuye kandi yiyongera;

20. Gusimbuka, gusimbuka bidasubirwaho.

Gutangiza porogaramu

Twakiriye CNCKAD kuva muri METALIX. Porogaramu ni porogaramu yuzuye ya CAD / CAM porogaramu yo gutangiza porogaramu kuva igishushanyo mbonera. Hamwe nimicungire yububiko bwibitabo, uburyo bwo guhitamo uburyo bwo guhitamo, gutezimbere inzira nindi mirimo, birashobora guhita bitangwa na CAD gushushanya NC uburyo bwo gutunganya. Urashobora kugera ku gice kimwe cyo gutangiza gahunda, guterana byikora hamwe na pack yuzuye.

Imikorere yo GushushanyaCNCKAD ibishushanyo bikomeye, byoroshye kandi bitangiza gukoresha, hiyongereyeho imikorere isanzwe yo gushushanya ukurikije ibiranga urupapuro, wongeyeho uburyo bwihariye bwo gushushanya nko gutemagura, kuzenguruka, mpandeshatu, inguni iburyo hamwe na kontour imiterere, gukata, kugenzura no gukosora byikora, gukata cyangwa gushiraho kashe, inyuguti zishinwa DXF / IGES / CADL / DWG dosiye nibindi ..

b) Imikorere yo Gukubita

Byerekanwe na punch yikora, ifu idasanzwe, indangagaciro zikora, kwimuka byikora, gukata inkombe, nibindi bikorwa.

c) Imikorere yo Kogosha

Automatic kontour kugenzura no gukosora ibipimo byubwoko bwibintu, ubunini, gukata kimwe, gukata, no kwimura shear, nibindi bikorwa, icyapa cyo gushyira mu bikorwa ibyuma byikora.

d) Gutunganya Amaposita

Gutunganya byikora cyangwa bikorana bikubiyemo inzira zose: kashe, laser, plasma, umuriro, gukata amazi no gusya.

Iterambere ryimyanya yambere irashobora kubyara ubwoko bwubwoko bwiza bwa NC, gushyigikira subroutine, gahunda ya macro, nko gutezimbere inzira yinzira no kuzenguruka byibuze, gushiramo inshinge, imashini yimashini ya vacuum nkibikoresho nigipimo cyo guhagarika igipimo.

Iyimura porogaramu kurindi mashini ikenera gukanda gake gusa nimbeba.Ibyo biva muburyo bwo gutunganya inyandiko ya CNCKAD, mugukuraho dosiye zirenze urugero za mudasobwa bigatuma imikorere irushaho kuba myiza.

e) Kwigana ibishushanyo bya CNC

Porogaramu ishyigikira igishushanyo mbonera cya porogaramu ya CNC, harimo kode ya CNC yandikishijwe intoki, inzira yo guhindura nayo iroroshye cyane, software irashobora guhita igenzura amakosa, nkibintu byatakaye clamp hamwe namakosa yintera, nibindi.

f) Guhinduka kuva NC kugera Gushushanya

Byaba intoki byanditse cyangwa izindi code ya NC, birashobora guhinduka mubice bishushanyo.

g) Raporo y'itariki

Urashobora gusohora amakuru yamakuru, harimo amakuru yose nkumubare wibice, gutunganya amakuru nkigihe, ibishushanyo mbonera nibindi ..

h) Ikwirakwizwa rya DNC

Kwemeza Windows interineti ya module yo kohereza, kugirango ihererekanyabubasha hagati ya PC nibikoresho byimashini biroroshye cyane.

1) 、 Shyigikira ibyitegererezo byose bya CNC turret punch, imashini ikata laser, imashini ikata plasma hamwe nimashini ikata flame nibindi bikoresho byimashini.

)

3) 、 Irashobora kwinjiza mu buryo butaziguye Autocad, SolidEdge, SolidWork na CadKey nibindi birimo porogaramu zose zizwi za CAD zakoze dosiye ishushanya.

4) 、 Porogaramu ishyigikira ibikoresho bitandukanye byo kugenzura imibare itandukanye, irashobora gushyira ibice bya NC kubyara dosiye zitandukanye, kubikoresho byinshi icyarimwe mugihe cyo gutunganya.

Gusimburana mu buryo bwikora

Iyo ingano yisahani ari nini kurenza urwego runaka, imashini ihita yongera guhagarara, hanyuma igahita itanga amabwiriza yumwanya; niba umukoresha afite ibyo asabwa bidasanzwe, birashobora guhindurwa cyangwa gusibwa kurutonde rwabo bwite.

Kwirinda clamp byikora

Amabwiriza yatanzwe muburyo bwikora bushobora gutuma clamp yirinda ahantu hapfuye, kugabanya imyanda; isahani ni igice cyangwa ibice byinshi byicyuma, irashobora kumenya imikorere yo kwirinda clamp.

Kwandika ibikoresho

Kugirango ugabanye guhindura ibintu muburyo bwo gutera kashe, tekinike yo gutunganya ibikoresho irashobora gukoreshwa, kandi igikoresho cyo gukata gishobora gukoreshwa imbere cyangwa inyuma yinyigisho zishami.

Uburyo bwo gutema

Uhujwe nigikorwa cyo gukubita inkoni isanzwe, gukubita byikora birashobora gukubita ibikoresho byacitse bikikije inkombe.

Umutuzo umwe wimuka mu buryo bwikora

Imashini yimuka yimuka irashobora kubyara porogaramu ihita yimura clamp binyuze mumabwiriza ya NC.

Minimun apfa kuzunguruka

Inzira ntarengwa yo gupfa irashobora kugabanya kwambara kuri sitasiyo yerekana kandi igateza imbere umusaruro.

Imikorere yubwoko bwinshi bwo gukubita

Imikorere yo gukubita inyabutatu, gukubita bevel, gukubita arc nubundi buryo budasanzwe kandi bunoze bwo gukubita.

Imikorere ya Auto-Punching ikomeye

Automatic Punching ibiranga harimo micro ihuza ihuza, guhitamo ubwenge mububiko hamwe nubutunzi bwo gutabaza hamwe nibindi bikorwa.

I) Igikorwa cyo gukata byikora

METALIX CNCKAD ikubiyemo AutoNest igizwe nigice cya plaque nyayo yikora optimizasiyo ya nesting software, ishobora kumenya impapuro zose zitezimbere uburyo bwa tekiniki.

1

2. Niba amashanyarazi adahagaze neza, stabilisateur irakenewe, niba hari amashanyarazi yamenetse, uburinzi burakenewe.

3.Amavuta ya Hydraulic :( SHELL) Tonna T220, Cyangwa andi mavuta yo kuyobora no gusiga amavuta rail

Amavuta yo gusiga : 00 # -0 # Amavuta yumuvuduko ukabije (GB7323-94), igitekerezo : munsi ya 20 ° C koresha 00 # Amavuta yumuvuduko ukabije, hejuru ya 21 ° C koresha 0 # Amavuta yumuvuduko ukabije

| Ikirango | Izina | Ijambo | Ubushyuhe |

| Igikonoshwa | EPO | 0 # Amavuta akabije | 21 ° C hejuru |

| Igikonoshwa | GL00 | 00 # Amavuta akabije | 20 ° C hepfo |

3. Ubushyuhe bwibidukikije: 0 ° C - + 40 ° C.

4. Ubushuhe bwibidukikije: ubuhehere bugereranije 20-80% RH (un-condensation)

5. Irinde kunyeganyega gukomeye cyangwa kubangamira amashanyarazi

6. Ibidukikije bifite umukungugu muto, nta gaze yuburozi

7. Tegura urufatiro ukurikije igishushanyo mbonera

8. Umukoresha agomba guhitamo umutekinisiye cyangwa injeniyeri wamahugurwa, amashuri yize agomba kuba nibura yarangije amashuri yisumbuye tekinike, akayategura igihe kirekire.

11.Gomba gutegura urufatiro ukurikije igishushanyo

12. Gufungura 65mm ya spanner wrench, inkoni ifasha nyuma yo gutwika, kugirango uhindure urwego shingiro.

13. Litiro zirenga 5 za lisansi isukuye, imyenda myinshi, imbunda, amavuta yo gusiga, litiro zigera kuri 1 kubikoresho byo gukuramo imashini.

14 hamwe na Ф10 * 300 hamwe na Ф16 * 300 inkoni z'umuringa zo gushiraho. Igiti kirekire (fuselage na beam bipakirwa ukundi, ariko kandi kugirango bategure ibice byoherejwe)

15 icyerekezo cyerekana (0-10mm intera), ikoreshwa mugukemura X na Y axis perpendicularity.

16 iyo ibikoresho bigeze muruganda, tegura traffic 20T cyangwa crane kubikoresho byo guterura

17.Niba V axis ifite moteri ya chiller yamazi, imiyoboro yo gukonjesha igomba gutegurwa igomba gutegurwa, ingano ni 38L

Ibindi bibazo bitarimo gukenera gusobanurwa no guhuza

Imashini ya CNC Turret Punch ; turret punch ; turret punch press imashini control igenzura ryumubare turret punch kanda ; servo Drive turret punch kanda ; turret punch kanda kugurisha

| Oya. | Ibisobanuro | Igice | Icyitegererezo cyimashini | ||

| MT300E | |||||

| 1 | Icyiza. Imbaraga | kN | 300 | ||

| 2 | Ubwoko Bukuru bwo Gutwara | / | Moteri imwe | ||

| 3 | Sisitemu ya CNC | / | Sisitemu ya FANUC CNC | ||

| 4 | Icyiza. Ingano yo gutunganya impapuro | mm | 1250 * 5000 (hamwe na reposition imwe) | 1500 * 5000 (hamwe na reposition imwe) | |

| 5 | Oya ya Clamp | oya. | 3 | ||

| 6 | Icyiza. Gutunganya Urupapuro | mm | 3.2 / 6.35 | ||

| 7 | Icyiza. Gukubita Diameter buri gihe | mm | Φ88.9 | ||

| 8 | Igitero gikuru | mm | 32 | ||

| 9 | Icyiza. Gukubita hit kuri 1mm Umwanya | hpm | 780 | ||

| 10 | Icyiza. Punch Ashyushye kuri 25mm Umuvuduko | hpm | 400 | ||

| 11 | Icyiza. Kwihuta | hpm | 1800 | ||

| 12 | Oya yo Gusimbuza Cylinder | gushiraho | 2 | ||

| 13 | Oya | oya. | 32 | ||

| 14 | Oya ya AI | oya. | 2 | ||

| 15 | Oya yo kugenzura Axis | oya. | 5 (X 、 Y 、 V 、 T 、 C) | ||

| 16 | Ubwoko bw'igikoresho | / | Ubwoko Burebure | ||

| 17 | Ubwoko bw'akazi | / | Munsi ya 3.2mm: Byuzuye guswera neza (Kuzamura imipira yo gupakira birashobora kongerwaho nkuburyo bwo guhitamo) | ||

| Hejuru ya 3.2mm: Imipira yuzuye ikora | |||||

| 18 | Icyiza. Kugaburira Umuvuduko | X Axis | m / min | 80 | |

| Y Axis | 60 | ||||

| XY Bishyizwe hamwe | 100 | ||||

| 19 | Umuvuduko wa Turret | rpm | 30 | ||

| 20 | Igikoresho cyo Kuzunguruka Umuvuduko | rpm | 60 | ||

| 21 | Ukuri | mm | ± 0.1 | ||

| 22 | Icyiza. Ubushobozi bwo Kuremerera | Kg | 100/150 kumupira ukora | ||

| 23 | Imbaraga nyamukuru za moteri | kVA | 45 | ||

| 24 | Uburyo bwo gukoresha ibikoresho | / | ubwoko bwigenga bwihuse bwo gusenya | ||

| 25 | Umuvuduko w'ikirere | MPa | 0.55 | ||

| 26 | Ikoreshwa ry'ikirere | L / min | 250 | ||

| 27 | Ubushobozi bwo kwibuka bwa CNC | / | 512k | ||

| 28 | Shakisha ahantu hapfuye | / | Y | ||

| 29 | Urupapuro rurwanya kwiyambura | / | Y | ||

| 30 | Kurwanya Urupapuro-Guhindura | / | Y | ||

| 31 | Urucacagu | mm | 5350 × 5200 × 2360 | 5850 × 5200 × 2360 | |

| Oya. | Izina | Ikirango | Gauge | ||

| 1 | Sisitemu ya CNC | UMUKUNZI | OI-PF | ||

| 2 | Umushoferi wa Servo | UMUKUNZI | AISV | ||

| 3 | Moteri ya Servo (X / Y / C / T axis) | UMUKUNZI | AIS (X 、 Y 、 T 、 C) Moteri idasanzwe ya V axis | ||

| 4 | Ubuyobozi | THK | HSR35A6SSC0 + 4200L (X: 2500) | ||

| HSR35A3SSC1 + 2060L-Ⅱ (Y: 1250) | |||||

| HSR35A3SSC1 + 2310L-Ⅱ (Y: 1500) | |||||

| 5 | Ballscrew | THK | BLK4040-3.6G0 + 3016LC7 (X: 2500) | ||

| BLK3232-7.2ZZ + 1735LC7T (Y: 1250) | |||||

| BLK3232-7.2ZZ + 1985LC7T (Y: 1500) | |||||

| 6 | Kubyara neza | NSK / Koyo | 25TAC62BDFC10PN7B / SAC2562BDFMGP4Z | ||

| 30TAC62BDFC10PN7B / SAC3062BDFMGP4Z | |||||

| 7 | Ibice byumusonga | Ibice bitatu | SMC | AC30A-03D | |

| Umuyoboro wa Solenoid | SY5120-5D-01 | ||||

| Muffler | AN10-01 | ||||

| Cylinder | CP96SDB40-80-A93L | ||||

| 8 | Sisitemu y'amashanyarazi | Kumena | Schneider | / | |

| Twandikire | Schneider | / | |||