Nubwo iteye imbere cyane mu bijyanye n'ubwiza bw'ibicuruzwa no gukora mu buryo bwikora ugereranije n'uburyo bwo gushyiramo no gufunga, haracyari ibibazo byinshi mu mikorere myiza yo guhanahana ubushyuhe no gukumira ivu ryinshi ry'imiyoboro y'amafi ivanze n'ivu bitewe n'ibintu nko kugorwa no gusudira mu mizi y'imiyoboro y'amafi ivanze n'ivu n'imibyimba mu mizi.

Umuyoboro w'ubushyuhe ni ubwoko bw'ikintu gihindura ubushyuhe. Kugira ngo hongerwe uburyo bwo kohereza ubushyuhe, ubuso bw'umuyoboro w'ubushyuhe bukunze kongerwaho amababa kugira ngo hongerwe ubuso bwo hanze (cyangwa ubuso bw'imbere) bw'umuyoboro w'ubushyuhe, kugira ngo hagerwe ku ntego yo kunoza uburyo bwo kohereza ubushyuhe, nk'uwo muyoboro w'ubushyuhe.

Nk'ikintu gihindura ubushyuhe, umuyoboro w'amazi ukoreshwa mu gihe kirekire mu bihe by'ubushyuhe bwinshi, nko mu gushyushya ubushyuhe hakoreshejwe boiler hamwe n'umuyoboro w'amazi ukoreshwa mu kirere gikaze, ubushyuhe bwinshi n'umuvuduko mwinshi ndetse no mu kirere cyangiza, ibyo bikaba bisaba ko umuyoboro w'amazi ukoreshwa mu gushyushya uba ufite ibimenyetso by'imikorere yo hejuru.

1), Kurwanya ingese

2), Kurwanya kwambara imyenda

3), ubushobozi bwo kwirinda gukora ku buryo bukabije

4), Ituze ryinshi

5), Ubushobozi bwo kurwanya ivumbi ryinshi

Ibyiza by'amababa yo mu cyuma kitagira umugese ya laser.

1. Hakoreshejwe ikoranabuhanga ryo gusudira hakoreshejwe laser ya pulse, gusudira hafi y'igice bikorwa icyarimwe, kandi igipimo cyo gusudira cy'igice cy'umuyoboro kigera kuri 100%.

2. Gusudira hakoreshejwe laser ni uruvange rw'ibyuma, imbaraga zo gusudira z'urupapuro rw'umuyoboro zishobora kugera kuri 600MPa.

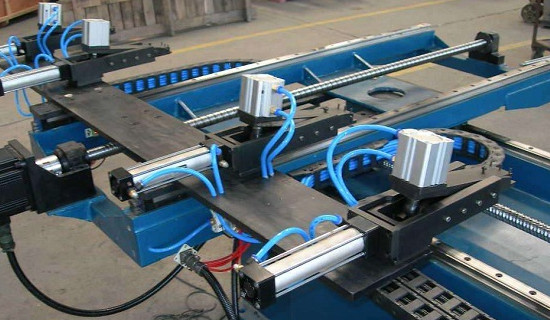

3. Imashini isudira hakoreshejwe laser ikoresha sisitemu yo kohereza servo, uburyo bwo kohereza bushobora kugera ku rwego rwa Kumi.

4. Intera y'agace k'agace k'umuyoboro w'ubushyuhe hakoreshejwe laser ishobora kuba ≤ 2.5mm, ahantu hashobora gushonga ubushyuhe kurusha aho umuyoboro w'ubushyuhe ukoreshwa inshuro nyinshi (intera y'agace ≥ 4.5mm) hiyongereyeho hafi 50%, ibikoreshwa bike kuri buri gace, bishobora kugabanya cyane ingano y'umuyoboro w'ubushyuhe.

Igihe cyo kohereza ubutumwa: 30 Nzeri 2022